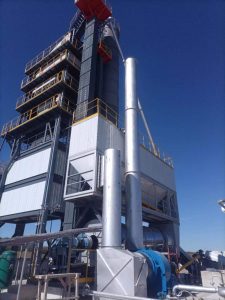

I-LB2500 asphalt mixing plant

Ukusebenza kahle okuphezulu; Ukuzinza okuphezulu; Ukuvikelwa kwemvelo; Ukonga amandla

- Uhlelo lokudla okubandayo

n Ama-aggregate adluliswa ngebhande lokuphakela elilawulwa imvamisa, ngaleyo ndlela kuqinisekiswe ingxenye eyinhloko enembayo ephezulu.

n Idivayisi eyisixwayiso ivimbela ibhande lokuphakelayo lisebenze ngaphandle komthwalo.

n I-Vibrator igcina izinto ezisetshenziswayo zingami isango noma zibambelele ezindongeni zomgqomo.

- Isistimu yokomisa

n Izindiza ezisezingeni eliphezulu ziqinisekisa iveli elilinganayo ukuze kube lula ukudluliswa kokushisa nokuvikela isigubhu ukuthi singagugi futhi.

n I-atomizer enengcindezi ephansi inika amandla uphethiloli ukuthi uvuthe ukuze usebenze kahle kakhulu.

n Isishisi sijwayelana nezibaseli ezihlukahlukene (udizili, uwoyela omkhulu, igesi yemvelo), futhi sinomsindo omncane okhishwayo.

n Isilinganiso sokwehlisa isishisi singu-10:1, esinciphisa ukusetshenziswa kwamandla.

- Uhlelo lokususa uthuli

n Uthuli olumahhadla luqoqwa umqoqi wothuli oyinhloko (isihlukanisi esine-inertial). Uthuli oluhle luqoqwa umqoqi wothuli wesibili (i-pulse jet baghouse). Isigcwalisi esitholiwe kabusha siyakwazi ukuphinda sifunzwe kungxube njengoba kudingeka. Lobu buchwepheshe baseJalimane buqinisekisa ukuphuma kothuli oluphansi (ngaphansi kuka-20 mg/Nm3).

n Isistimu yokuvikela izinga lokushisa ivikela isihlungi ekushiseni ngokweqile ngokulawula i-valve yomoya obandayo nesishisi.

- Isistimu yokuphakamisa i-aggregate eshisayo

n Isikheshi sebhakede se-Double-chain sidlulisa okokusebenza ngokuzinzile futhi sikhipha umsindo omncane.

n Amabhakede enziwe nge-wear resistant steel futhi ngaleyo ndlela abe nempilo ende.

- Isistimu yokuhlola

n Isikrini sethu sokudlidliza esithambekele sishayelwa ama-eccentric shafts noma amamotho amabili angalingani. Zombili zinokusebenza kokuhlola okuphezulu.

n Imeshi yesikrini kulula ukuyishintsha.

n Ukuthwala kuwukunakekela okuphansi.

- Isistimu yokugcina ehlanganisiwe ehlanganisiwe

n Isikhombi sezinga lomgqomo sidlulisela isignali kusistimu yokulawula ngesikhathi.

n Ama-aggregate aphuma ngokuzenzakalelayo nge-chute echichimayo lapho isisele sigcwele.

n Izilinganiso zobukhulu obukhulu ziwela ngokuzenzakalelayo nge-chute ye-aggregate ewusayizi omkhulu.

- Isistimu yokukala

n Izikali zamaminerali zinomsebenzi wokunqwabelana kanye nomsebenzi wokulungisa ozenzakalelayo endizeni. Ezitshalweni ezinkulu, sisebenzisa inhlanganisela yezikali ezihlanganisiwe ezimbili. Isikali sinembile sibe phakathi kuka-±2.5%.

n Izikali zokugcwalisa zinamaphuzu angu-3 okulinganisa nomsebenzi wokunqwabelana. Isikali sinembile sibe phakathi kuka-±2%.

n Izikali zebhituni ziyizikali ezinobubanzi obukabili futhi zinamaphuzu angu-3 okulinganisa. Isikali sinembile sibe phakathi kuka-±2%.

- Isistimu yokuhlanganisa

n I-twin-shaft mixer isebenza kahle kakhulu kanye nezindleko zokuguga eziphansi.

n Amapuleti e-liner nama-agitator paddles enziwe nge-Nichrome engagugi, ngaleyo ndlela aqinisekise impilo ende yesevisi.

- Isistimu yokugcina ingxube eshisayo

I-Loading silo ivalekile. Izinga lokushisa lezinto ezixutshiwe liyehla lingabi ngaphezu kwamadigri angu-5 phakathi namahora angu-12, lapho izinga lokushisa elizungezile lingu-15—25℃.

- Isistimu yokulawula

Ikhabhinethi yethu ye-PLC yamukela izingxenye ze-Siemens futhi isebenziseka kalula. I-automatic, i-semi-automatic kanye nezilawuli ezenziwa ngesandla ziyatholakala. Isistimu yokulawula nayo inemisebenzi enjalo: ukugcinwa kweresiphi, ukulungiswa okuzenzakalelayo endizeni, ukulungiswa kwepharamitha, ukulinganisa isikali, itiyela ukuze kuhlanganiswe umkhondo wesilinganiso, ukuxilongwa okuzenzakalelayo kwephutha, i-alamu ezenzakalelayo nokuphrinta amashidi.

- Isevisi

Isitshalo sethu siwumklamo we-modular. Ukufakwa, ukugcinwa, kanye nokuthutha kulula kakhulu. Ithimba lethu lesevisi liqeqeshwe kahle ukusiza amakhasimende ngokuthenga, ukusebenza, nokugcinwa kwemikhiqizo.