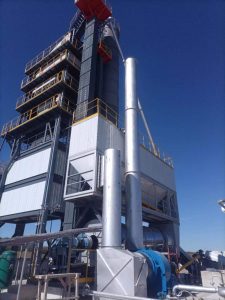

LB2500 asphalt mixing plant

High efficiency; Superior stability; Environment protection; Energy saving

- Cold feeding system

n Aggregates are conveyed by frequency-controlled feeding belt, thus ensuring a high precision primary proportion.

n Warning device prevents feeding belt running without load.

n Vibrator keeps materials from jamming the gate or clinging to the bin walls.

- Drying system

n State-of-the-art flights ensure an even aggregate veil to facilitate heat transfer and protect the drum against wear and tear as well.

n Low-pressure atomizer enables the fuel to combust for peak efficiency.

n The burner adapts to a variety of fuels (diesel, heavy oil, natural gas), and has low noise emissions.

n The turndown ratio of burner is 10:1, which reduces energy consumption.

- Dust removal system

n Coarse dust is collected by primary dust collector (inertial separator). Fine dust is collected by secondary dust collector (pulse jet baghouse). The reclaimed filler is able to be re-fed to the mix as needed. This German technology ensures low dust emission (less than 20 mg/Nm3).

n Temperature protection system protects filter from overheating by controlling cold air valve and burner.

- Hot aggregate elevating system

n Double-chain bucket elevator conveys material stably and has low noise emissions.

n The buckets are made of wear resistant steel and thus have a longer lifetime.

- Screening system

n Our inclined vibrating screen is driven by two eccentric shafts or two unbalanced motors. Both have high screening performance.

n Screen mesh is easy to replace.

n Bearing is low-maintenance.

- Hot aggregate storing system

n The bin level indicator transmits signal to the control system timely.

n Aggregates flow out automatically through the overflow chute when the silo is full.

n Oversize aggregates drop automatically through the oversize aggregate chute.

- Weighing system

n Mineral scales have accumulation function and automatic in-flight correction function. For large plants, we adopt the combination of double aggregate scales. The scale is accurate to within ±2.5%.

n Filler scales have 3 points of measurement and accumulation function. The scale is accurate to within ±2%.

n Bitumen scales are dual-range scales and have 3 points of measurement. The scale is accurate to within ±2%.

- Mixing system

n The twin-shaft mixer has high mixing efficiency and low wear costs.

n The liner plates and agitator paddles are made from wear-resistant Nichrome, thus ensuring a long service life.

- Hot mixture storing system

The Loading silo is insulated. The temperature of mixed material drops no more than 5 degrees within 12 hours, when the ambient temperature range is 15—25℃.

- Control system

Our PLC cabinet adopts Siemens components and is user-friendly. Automatic, semi-automatic and manual controls are available. The control system also has such functions: recipe storage, automatic in -flight correction, parameter adjustment, scale calibration, bitumen to aggregate ratio trace, automatic fault diagnosis, automatic alarm and sheet printing.

- Service

Our plant is modular design. Installation, maintenance, and relocation are very convenient. Our service team is well trained to help customers with products purchase, operation, and maintenance.